Furthermore the VAE polymer improves the abrasion and impact resistance of pervious concrete which results in lower surface raveling and ultimately improves the life cycle of the pervious pavement. Pervious Pavement Design Guidance.

Stormwater Management Pervious Pavement

Structed using porous concrete pavement approximately 49 m by 64 m 160 ft by 210 ft.

. However the strength of the material is relatively low because of its porosity. Presented as a system rather than just another pavement design guide. Pennsylvania State Transportation Innovation Council STIC Subject.

57 stone 475 to 250 mm and followed by at least an 864-mm 34-in thick layer. Overall the past studies indicated that pervious concrete mix is a very promising candidate to be used as a pavement material in low-volume roads such as local streets pedestrian walkways and driveways and possibly inarterials. Pervious concrete pavement is a unique and effective means to address important environmental issues and support green sustainable growth.

Pervious concrete is also widely used in Europe and Japan for roadway applications as a surface course to improve skid resistance and reduce traffic noise. Adopted from the ACI guide for design of conventional concrete parking lots. See Design Checklist Pervious pavement also referred to as permeable pavement contains pores or separation joints that allow water to flow through and seep into a base material typically gravel or drain rock.

Comparaive properies of 3 major permeable pavement types. The R ² value for 2890 and. A typical cross section of the porous concrete pavement system consists of a 152-mm 6-in thick layer of porous concrete a 51-mm 2-in thick layer of AASHTO No.

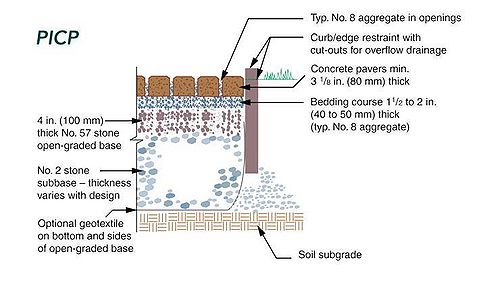

Pervious concrete pavement design pdf B. Permeable Interlocking Concrete Pavements PICP Unlike other systems the paving stones that comprise the wearing surface of the pavement are not permeable. Implementation of design standards for pervious concrete pavements.

38 Removal of Heavy Metals from Stormwater Using Porous Concrete Pavement A considerable amount of studies have been pavement had a cross-section of 2 ft 2 ft and a performed on the removal effectiveness of height of 25 ft. Pervious Concrete Comply with American Concrete Institute Specification for Pervious Concrete Pavement or recommendations of the Wisconsin or. KeywordsPervious Concreteporosity porousmix design permeability stormwater.

Permeable Pavement 1 Revised. Permeability is achieved through openings in the pavers or the joint spaces between the blocks. Deicing agents that contain fertilizer ingredients such as Ammonium Sulfate and Ammonium Nitrate cause chemical deterioration to any Portland cement-based concrete pavement and.

Mix Design Development for Pervious Concrete In Cold Weather Climates 7. Design Factor Porous Concrete PC Pervious Asphalt PA Permeable interlocking concrete pavers PICP Scale of application Small and large scale paving applications Small and large scale. By capturing stormwater and allowing it to seep into the ground porous concrete is instrumental in recharging groundwater reducing stormwater runoff and meeting US.

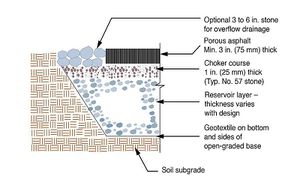

Porous asphalt pavement. Types of pervious pavement include porous asphalt and concrete open joint pavers interlocking concrete or permeable. The pervious concrete installed at 3 locations in DC with the optimal pervious concrete mix yielded average infiltration rates between 861 and 2087 inhr.

Pervious concrete which is referred as enhancing porous concrete gap graded concrete or no fine concrete is a step forwards minimizing urban flooding. Deicers containing magnesium chloride calcium magnesium acetate or potassium acetate should never be used on pervious concrete pavement. The advantages of pervious concrete can be classifi ed into 3 basic categories.

PERVIOUS CONCRETE PAVEMENT WITH DETENTION. The proposed design thicknesses will help designers to evaluate the required PC pavement thickness based on the expected traffic volume and PC mechanical properties but needs to be updated using a fatigue model for pervious concrete. Hardened densitythe dry density of pervious concrete.

Early-entry dry-cut sawa tool designed to produce joints in concrete commencing 1 to 4 hours after finishing. Abstract Portland cement pervious concrete PCPC is being used more frequently due to its benefits in reducing the quantity of runoff water. Pavement Surface Design Permeable pavement surface materials and installation shall be in accordance with industry standards for the ir intended use.

Pervious concrete pavement has been used for over 30 years in England and the United States. Porous concrete pavement systems for hydrocarbons nutrients fecal coliforms metals and various contaminants 5-7. On level subgrades stormwater storage is provided in the pervious concrete surface layer 15 to.

Majority of pervious concrete needs little or no maintenance Handled in original design and site plan Prevent flow of debris onto pavement surface Clogged pervious concrete Vacuuming surface Pressure washing Maintenance practices still under development. Design and Use of Pervious Pavements Author. Promote the use of pervious pavements which allow water to pass through the pavement to reduce surface runoff and to recharge groundwater sources.

The pervious concrete mix is prepared using aggregates conforming to IS- 383 cement polyvinyll alcohol PVA silica fume and zeolite as admixture. Tensile strength ranges between 202 MPa to 399 MPa. Life and durability of the pervious pavement.

Aggregate that is uniform in size gap-graded is preferred for a pervious concrete mixture. Visit wwwctreiastateedu for color PDF files of this and other research reports. The reservoir typically allows the water to infiltrate into the soil subgrade.

It is intended to supplement American Concrete Institute ACI 522R-10 Report on Pervious Concrete and ACI 5221-13 Specification for Pervious Concrete Pavement. Pervious concrete is a mixture of Portland cement. Permeable Pavement Design Objective Permeable pavement captures stormwater through voids in the pavement surface and filters water through an underlying aggregate reservoir.

Typical cross section of pervious concrete pavement. It is typically designed to capture rainfall on the pavement surface area but may also accept run-on from adjacent impervious areas and other hardscapes sidewalks rooftops or gutters. Environmental Protection Agency EPA.

Permeable Pavement 190 Tennessee Permanent Stormwater Management and Design Guidance Manual Table 2. Pervious pavement is designed primarily to promote stormwater infiltration and improve the quality of stormwater runoff. Volume of pervious concrete based on the theoretical mixture proportions and design density and where the unit volume includes the volume of the solids and the voids.

Area credit assigned to pervious concrete by local municipality is 50 If parking lot is made of pervious concrete the owner would be given area credit equal to 50 of the pervious concrete area 10000 x 05 5000 sqft. Structurally PICP is a flexible pavement like asphalt. The coefficient of permeability also ranges from 324 to 565 mms.

Design Section For Pervious Concrete Pavement System Download Scientific Diagram

Nr Pervious Hardscape Materials Nj Green Building Manual

Pdf Structural And Hydrological Design Of Sustainable Pervious Concrete Pavements Semantic Scholar

Design Specifications For Permeable Pavement Minnesota Stormwater Manual

Pdf Pervious Concrete Pavements

Design Criteria For Permeable Pavement Minnesota Stormwater Manual

0 comments

Post a Comment